Modern curved staircase

If you have a tiny space to dedicate to your new staircase but still want to achieve an astonishing design, here is our proposal: a modern curved staircase for small spaces.

Staircase project ref. Dublin Stairs – Bollum Lane Modern curved staircase.

Our oak and steel staircase with twisted architectural design is perfect for tiny but unique homes. Here below you find more details on this project.

Staircase project details

Type of building: self-build single family dwelling

Staircase Architectural style: modern staircase

Location: Dublin – Ireland

Our clients say…

“We self-built our house over the course of 5 years, so everything was quite drawn out. It was an absolute pleasure to deal with Grand Design Stairs Specialist Team. They were extremely patient as we went through 4 different iterations of stair design. We couldn’t be more happy with the service and quality of the product from Grand Design Stairs. It turned out even better than we thought. The install was straight forward (less complicated then IKEA) and now we have a real show piece in the house.”

Nathan and Agnieszka Mur.

Home owners – Rush, Dublin, Ireland

Staircase Project Development – Dublin Stairs – Bollum Lane

When contacting us, our clients (a family with two little kids) had a very clear vision of his staircase project in his mind.

They wanted a unique curved staircase, able to give the wow-factor to the entire house.

Light and white colours were a must in this project.

The main problem was the space. They wanted a curved impressive staircase, but at the same time they did not want the staircase to occupy a big area, as the available space in the room was limited.

A possible option would have been a wood staircase similar to our Moscow Stairs Smolensk Square project, which also have an impressive staircase design. The clients however preferred to have steel stringers and railing, instead of oak stringers and glass.

The house was a self-building project that the customers started in their “free-time” after work, so they needed all our expertise in designing a perfect staircase solution at an affordable budget.

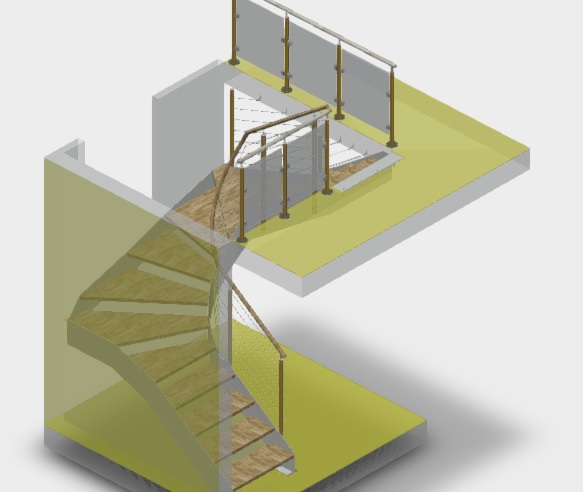

Sharing our basic staircase ideas with them, we came up with the final solution of positioning the staircase in the corner, against the walls but close to a big window. Having the staircase following the wall lines would avoid the cost of an external railing and would leave a lot of free space in the room.

On the other hand, the customers did not want a traditional staircase, so we had to plan something special to make their interior design unique.

Our idea was to design the internal stringer with an helical shape to make a spectacular U-turn.

The curved and shaped wooden handrail would add all the elegance we needed.

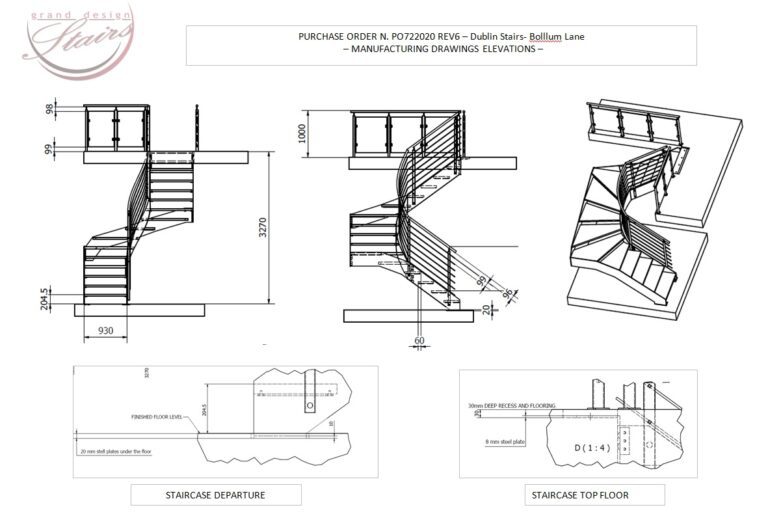

We worked on the initial staircase drawings provided by the customers and issued our initial staircase plan drawings and a 3D staircase design for them. They were very pleased with it, just wanted to change the stringers color and have them white. This was a perfect decision to give more light and elegance to the entire staircase design.

Treads and handrail were decided to be oak stained to match the oak floor they had both on ground and first floor. On the top floor, the landing balustrade was designed to have glass panels to allow as much light as possible coming through.

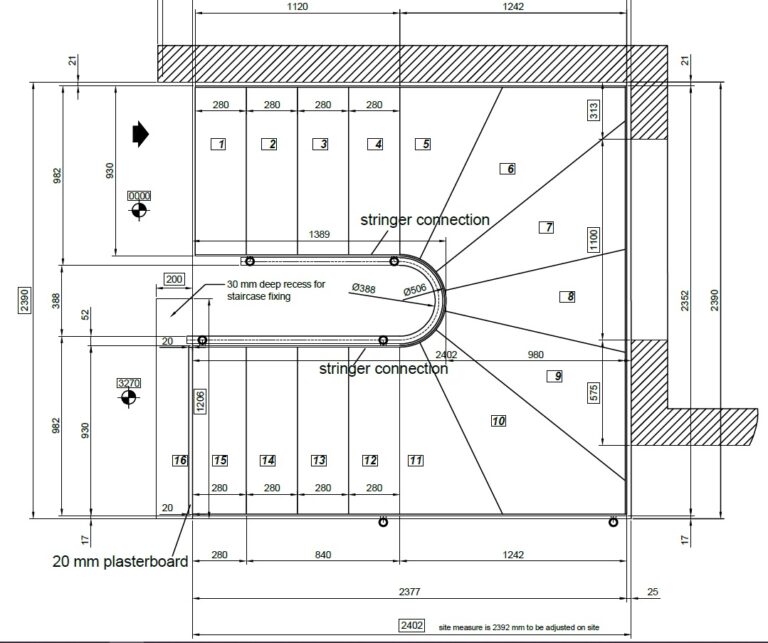

When the site was ready, with plastered walls and screed applied on floors, the client was able to take the measures we needed to proceed with our shop-drawings.

The client wanted to clad the walls with wonderful white tiles, so we had to incorporate the tiles wall into our design. Eventually, it was time to get drawings approved and start production.

The staircase manufacturing took around seven weeks; two weeks were needed to complete the engineered curved stringer and the curved oak handrail. We pre-fitted the staircase in the factory to be sure that everything was perfect, so that the installation would have been easy and straight forward. Hence the customer was a DIY man, he decided to install the staircase by himself with just the help of a friend, a carpenter who could help and give advice on how to organise the site to start installation of the staircase stringers.

Staircase Installation – Dublin Stairs – Bollum Lane

Following our guidelines and installation drawings, the client was able to install the staircase and the top landing balustrade in just few days. The final result was stunning and the client was absolutely thrilled as he could finally see the staircase he had dreamt of just in front of his eyes. In fact the staircase was perfect and the helical twisted design added a touch of exclusivity to the entire home decor.

The family could begin a new life in their new stunning home.

Staircase Design Features

We thereafter introduced to the customers many options available in terms of materials, colors and finishes. As the customers already had a clear idea of what they wanted to achieve, the final choice was restricted to two colours for the steel staircase components and another two for the wooden staircase parts finishes. Afterwards we sent some samples to the customers and they came back with their choice: white for the stringers, black for the steel railing and brushed oak stained to light walnut for the wood.

Staircase technical data sheet – Dublin Stairs – Bollum Lane

| Staircase Details | Clients preferred options | Other options & up-grades |

|---|---|---|

| Floor to floor height | 3270 mm | any measure available |

| Ceiling opening | 2400 x 2400 mm | any measure above 2400 mm |

| Risers | 16 @ 204.4 mm | 180 – 220 mm |

| Staircase width | 950 mm | 800 – 1200 mm |

| Staircase stringers | powder coated steel | stainless steel |

| Treads | oak | beech, iroko, walnut |

| Railing model | powder coated steel posts & horizontal rods | glass railing |

| Handrail | oak | stainless steel, pc steel |

| Top Floor landing balustrade | powder coated steel posts, oak handrail and glass panels | Frameless glass top or side mounted |

| Riser infill | Plexiglas riser bars | Wood, glass |

| Steel staircase parts finishes | powder coated matt white for stringers, powder coated matt black for railing | Light or dark grey, rust effect |

| Wooden staircase elements | brushed oak stained to light walnut | beech, iroko, walnut smooth or brushed in different wood stains |

| Glass stairs components | low iron safety glass | Satin or coloured glass |

| Additional | window guard-rail | Led lights on treads |

Order Process – How it worked – Dublin Stairs – Bollum Lane

Step 1– staircase details

Surfing the internet looking for ideas for their new residential staircase, suddenly the customers came across an image of one of our domestic staircase projects and were impressed by the distinctive look we were able to give to a curved staircase. They sent us an email with general information on their new build project and giving details on what they wanted to achieve with the staircase design. They also sent a sketch drawing with basic measures.

Step 2- staircase quote

We finalized some details with the customers and then studied the project with our designers and engineers. After an initial evaluation, we were able to issue our quote and send it to the customers for their review and approval.

Step 3 – Staircase Concept Design

Once the budget for the staircase was decided and our quote confirmed, we began working on the initial drawings to be presented to the customers. In order to let the clients have a precise visualization of what we were designing, we issued a 3D staircase render. The customer was happy with it, but wanted to change the railing from stainless steel to black powder coated. The final design was then completed and approved.

Step 4 – Staircase Production drawings

Our technical department double checked all measures and completed the staircase drawings in the AutoCAD file. Additionally, plans and elevation drawings were supplied to customers for their final check on site. As the customers were able to take very accurate measurements, a site survey from our technicians was not needed. However, as a standard procedure, our technicians can go directly to the site to carry out final measures and to give information to the builders on how to prepare the site to receive the staircase.

Step 5 – Staircase Construction

As we usually do for our customized staircases, we pre-fitted all staircase components in the factory. Holes drilled, stair components welded, steel and stainless steel parts satin finished, oak handrail tested, everything done to be 100% sure that installation on site will be fast and straight-forward.

Step 6 – Staircase shipment

Afterward, the stairways components were carefully packed and put inside a wooden case, at last ready to be shipped. A detailed packing list was provided, so that upon staircase delivery, customers could check that all stair parts were delivered and all was ok.

Step 7 – Staircase Installation

Following the staircase installation guide and stairs fitting drawings, the customer installed the staircase step by step, starting from the steel stringers which are the main support for the whole staircase. Basically as lifting tool, he only needed a hoist to lift the steel stringers, which were very heavy. With two people working on the installation every other day and not full time, they could complete the job in 10 days. Project ref. Dublin Stairs – Bollum Lane.

However, among our various services, we also offer the installation carried out by our team of installers. This gives a full service to our customers, from the design stage to the installed staircase.

Get started with your staircase project …